PES Hollow Fiber Membrane - Why is it ideal for high-efficiency filtration

2025-10-21

MS

8

1, What is PES membrane?

A PES membrane refers to a polyethersulfone membrane, which is a type of synthetic polymer membrane made from the polymer polyethersulfone (PES). These membranes are widely used in filtration processes due to their unique properties. PES membranes are favored in situations where chemical resistance, high mechanical strength, and thermal stability are essential. Their relatively low fouling tendencies compared to other types of membranes, like polyamide, also make them a preferred choice in many applications.

Membrane Solution is developing the PES membrane in both flat sheet and hollow fiber type, catering to the variety demands in market:

2, What is PES Hollow Fiber Membrane?

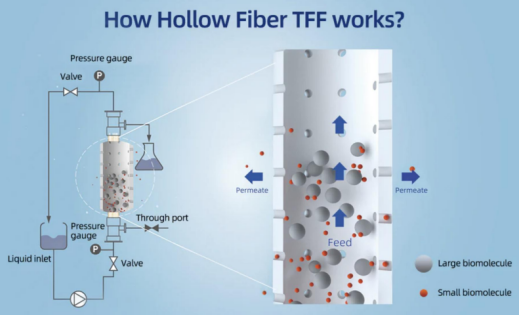

A PES hollow fiber membrane is a specific type of polyethersulfone (PES) membrane that is made in the form of hollow fibers. The membrane consists of long, thin fibers that are hollow in the center. This structure allows for a high surface area in a compact space, making them very efficient for filtration. PES hollow fiber membranes can have various pore sizes depending on their application. They are commonly used in microfiltration (MF) and ultrafiltration (UF), with pore sizes ranging from 0.1 µm to 0.01 µm.

3, PES Hollow Fiber Membrane Filter

Hollow fiber filter is a membrane filter composed of multiple groups of parallel hollow fiber membranes. It can generally be divided into ultrafiltration (1-1000kD) and microfiltration (0.1-1.0um).

4, Filtration Principle of PES Hollow Fiber Membrane Filter

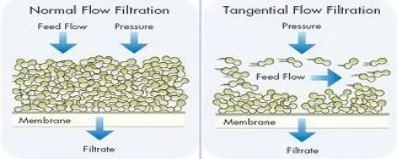

According to the flow direction of the liquid, filtration can be divided into normal flow filtration (NFF) and tangential flow filtration (TFF). Hollow fiber filter is tangential flow filtration (TFF).

Tangential Flow Filtration (TFF) is a type of membrane filtration process in which the feed solution flows parallel (tangential) to the surface of the membrane, rather than perpendicular (normal flow filtration). This technique is commonly used for concentration, purification, and separation of biological or chemical products.

5, Why is PES Hollow Fiber fiber idea for high-efficiency filtration?

PES hollow fiber membranes are particularly well-suited for high-efficiency filtration due to their unique structural, material, and functional properties. These properties make them ideal for applications that require consistent, high-performance filtration, especially in challenging or large-scale processes like biotechnology, pharmaceuticals, water treatment, and food processing.

Here are the key reasons why PES hollow fiber membranes are excellent for high-efficiency filtration:

1. High Surface Area for Filtration: The hollow fiber structure provides a very high surface area-to-volume ratio compared to flat-sheet membranes. This allows for greater filtration capacity in a compact space. The high surface area increases the filtration rate, allowing for more efficient processing of large volumes of liquid or gas, which is particularly beneficial in industrial-scale operations.

2. Reduced Fouling and Increased Durability

Tangential Flow Filtration (TFF): In hollow fiber systems, the tangential flow (feed flowing parallel to the membrane) helps reduce the buildup of particles and solutes on the membrane surface, a phenomenon called fouling. This reduces the likelihood of clogging, maintaining high filtration efficiency over time.

Shear Force: The fluid dynamics within the hollow fibers generate shear forces that help to continuously clean the membrane surface by dislodging particles, reducing fouling, and enhancing performance.