Special Requirements and Solutions for MLCC Slurry Filtration

2024-10-15

MS

53

What is MLCC (Multilayer Ceramic Capacitor)

MLCC(Multilayer Ceramic Capacitor) also known as chip capacitors, accounts for about one-third of the passive component market, with a global market size exceeding ten billion dollars. Thanks to its characteristics of high voltage resistance, compact size, long lifespan, and wide capacitance range, MLCC are widely used in consumer electronics, industrial applications, communications, automotive, and military sectors, earning the nickname 'rice of the electronics industry.

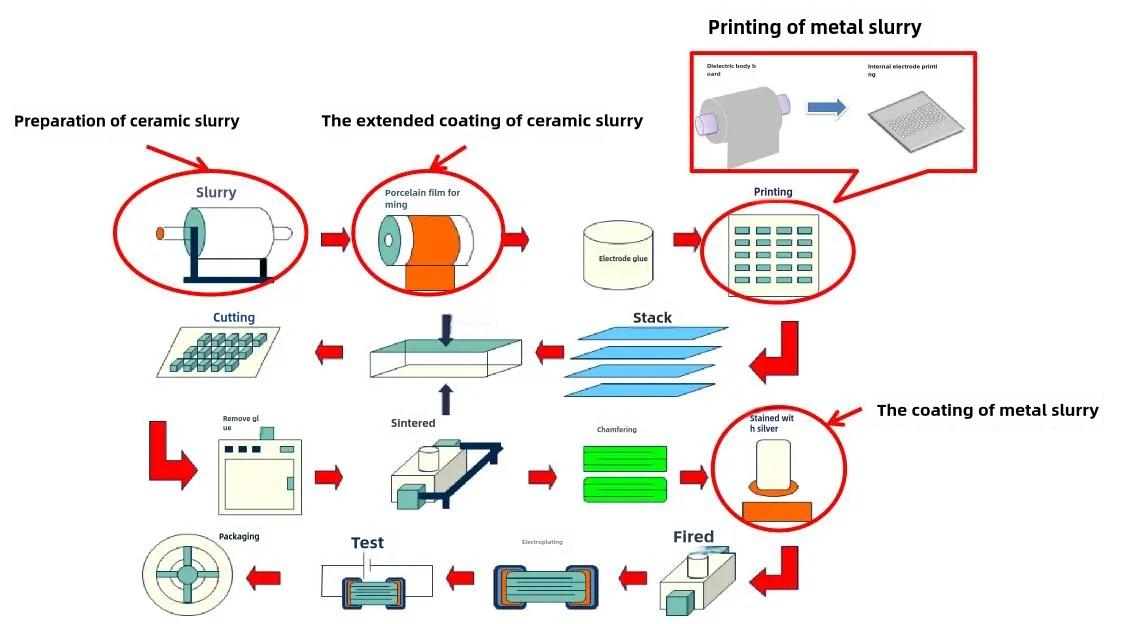

MLCC Production Process and Role of Ceramic and Metal Slurries

In the manufacturing process of MLCC, ceramic slurry is used in the preparation and casting coating stages, while metal slurry is utilized for printing the inner electrodes and coating the outer electrodes.

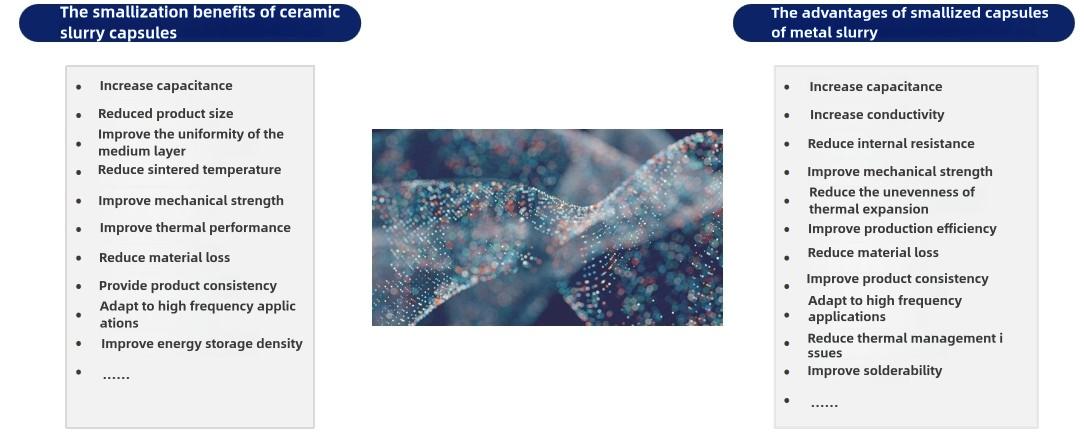

Particle Miniaturization: Enhancing Capacitance and Layer Density in MLCC

The miniaturization of ceramic slurry particles offers benefits such as increased capacitance, reduced sintering temperature, and decreased losses. In contrast,the miniaturization of metal slurry particles enhances conductivity, reduces internal resistance, and supports high-frequency applications. Currently, Japanese suppliers like Murata and TDK can achieve over 1000 layers with a 1μm thin film dielectric. According to information disclosed on Samsung's official website, they can achieve a 600-layer process, while domestic manufacturers have only managed a few hundred layers at best. Therefore, MLCC Manufacturer are focusing on miniaturizing and nanosizing slurry particles to reduce dielectric thickness and increase layer count.

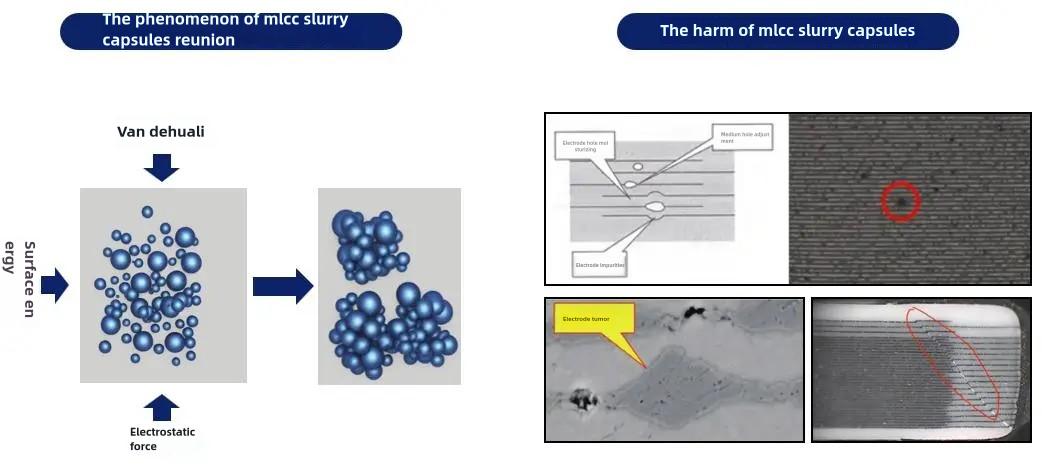

Challenges Posed by Particle Aggregation in High-Performance MLCC

Although miniaturized and nanosized slurry particles offer numerous benefits, it is also well-known that smaller particles tend to aggregate due to van der Waals forces, surface energy, and electrostatic forces. The aggregation of slurry particles can lead to issues such as voids in the ceramic dielectric, impurities in the electrodes, and device cracking. These adverse phenomena pose significant obstacles to improving the yield and advancing the high-end capabilities of MLCC

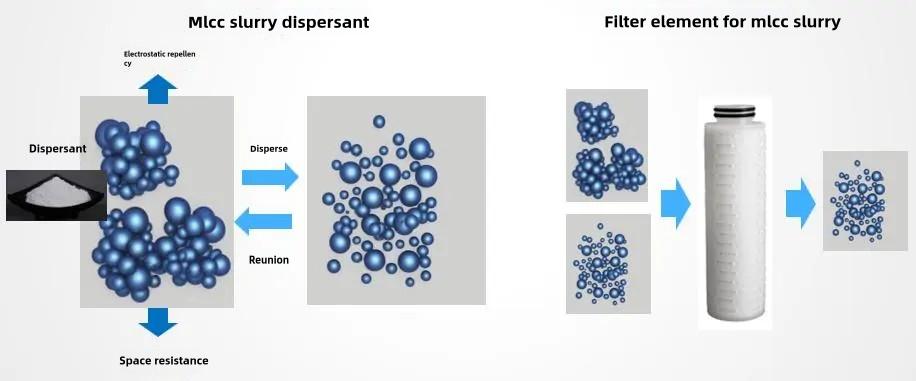

Approaches to Mitigating MLCC Slurry Particle Aggregation

How can the aggregation of MLCC(Multilayer Ceramic Capacitor) slurry be addressed? There are generally two solutions. The first involves the use of dispersants, which work by adding components that disperse aggregated particles through electrostatic repulsion, steric hindrance, or a combination of both. However, due to the progressive effect, aggregated particles will eventually reach a dynamic equilibrium of aggregation and dispersion after being dispersed a few times. To address particle aggregation at this dynamic equilibrium, the second solution involves using filters to remove the aggregated particles.

Requirements of MLCC Slurry Filtration

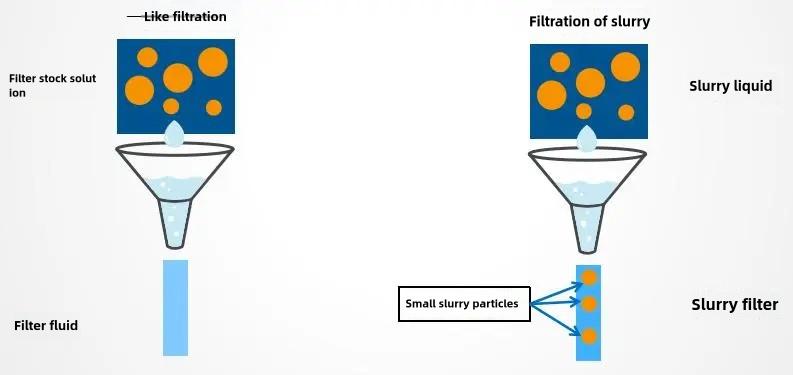

Slurry filtration differs from conventional filtration due to several special requirements. First, it requires selective and graded filtration. In typical filter cartridge filtration, the goal is to remove as many particles as possible from the original solution. However, slurry filtration is different; it needs to eliminate larger aggregated particles while retaining the dispersed and useful smaller slurry particles. This sets a higher standard for filtration, known as the graded filtration requirement.

Impact of Slurry Viscosity on Filtration Efficiency

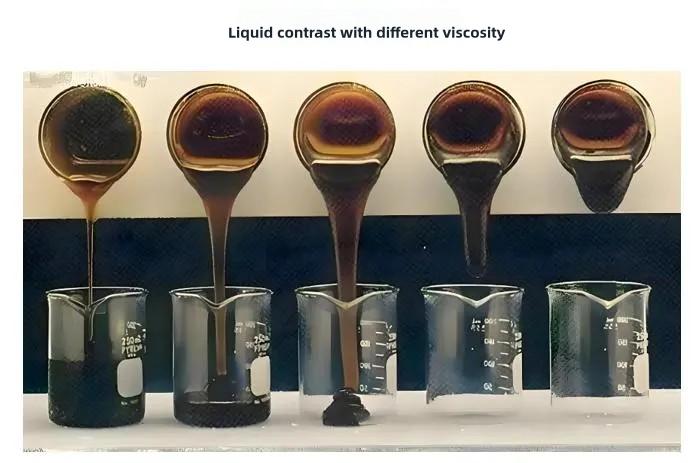

Second, the viscosity of slurries differs from that of typical liquids or solutions. Since different manufacturers use varying slurry formulations, the viscosities can vary significantly, impacting the filtration process. Higher viscosity slurries increase pressure differentials during filtration, thereby reducing the filtration rate. Additionally, due to the differences in viscosity, the filtration paths can also vary; more viscous slurries may bypass pores, diminishing filtration effectiveness. Therefore, specific filtration paths need to be designed to accommodate the unique viscosity characteristics of the slurries.

Custom Filtration for Varying Slurry Particle Size Distributions

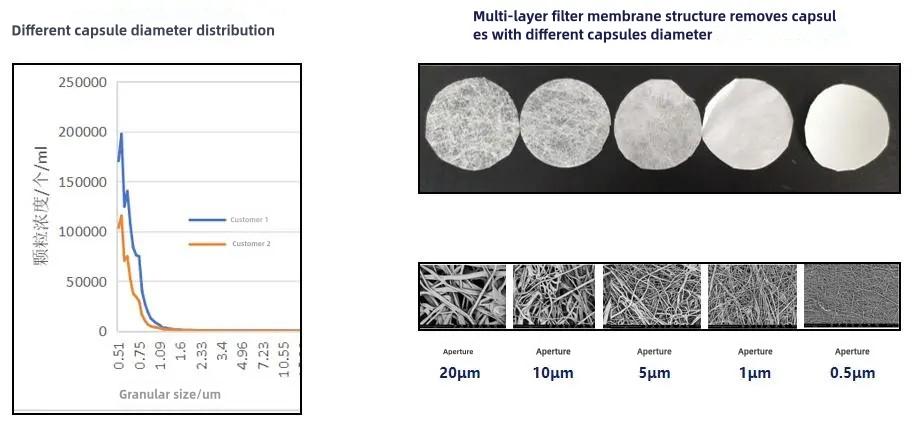

Third, the particle size distribution of slurries varies and requires customized development. Different MLCC manufacturers have unique slurry formulations, resulting in distinct particle size distributions for their slurries. Even within the same manufacturer, the particle size distributions of ceramic slurry, inner electrode metal slurry, and outer electrode metal slurry can differ across various processes. This necessitates the use of different multilayer filter membrane structures to classify and screen the slurries, removing harmful aggregated large particles while retaining useful fine particles.

Key Factors in Implementing Effective MLCC Slurry Filtration Solutions

Given the special requirements for MLCC slurry filtration, how can we effectively carry out this filtration process? Several key implementation points need to be addressed:

First, having extensive experience in the slurry filtration field is essential. This ensures the availability of various filter structures, such as melt-blown filters, wound filters, and pleated filters, which are necessary for the slurry preparation process, as well as bag filters required for the casting and coating stages. With our years of experience serving major clients, Membrane Solutions has built a vast product portfolio that meets different precision requirements, interface types, and filter membrane combinations to cater to the diverse needs of MLCC manufacturers. We offer melt-blown filters with gradient pore sizes and high dirt-holding capacity, wound filters with layered structures and efficient retention, pleated filters with gradient pore sizes and long service life, as well as bag filters that are easy to install and remove while providing high precision.

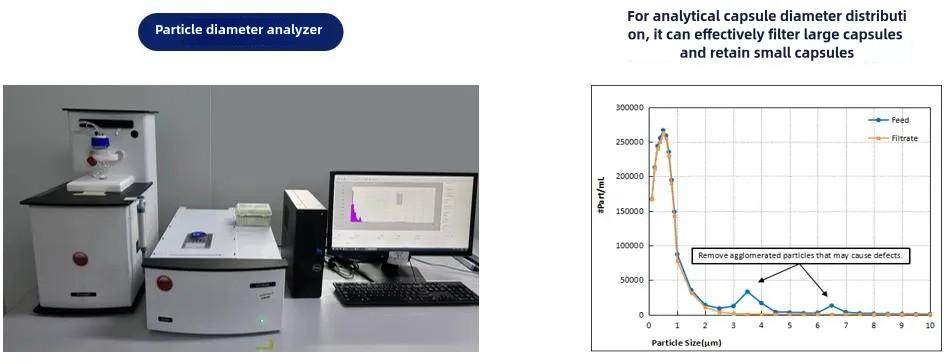

Customization and Analysis Capabilities in Filtration Design

Second, there is the capability for customized development based on pore size analysis. As mentioned earlier, different MLCC manufacturers use slurries with varying particle size distributions. At membrane solutions, we utilize particle size analyzers to conduct size analyses of the slurries, enabling us to specifically develop filter structures that effectively remove harmful large particles while retaining useful small particles.

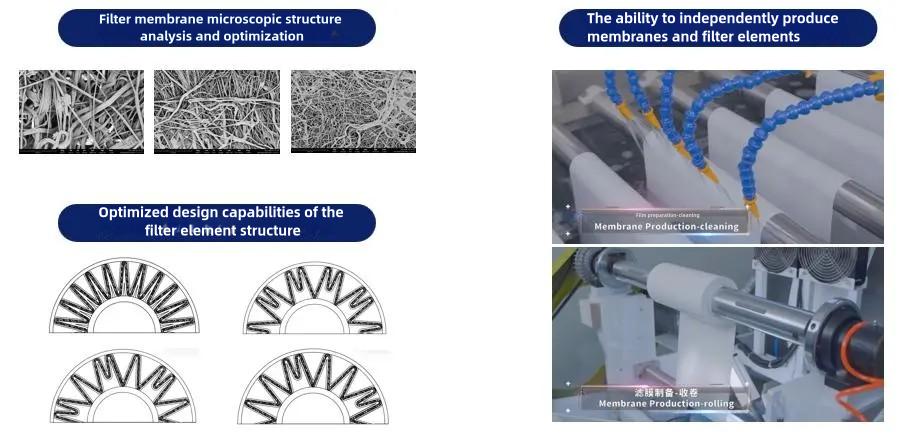

Independent R&D for Quality in Membrane and Cartridge Production

Additionally, the third key implementation point for slurry filtration is the capability for independent research and development of membrane filter and filter cartridge production. In terms of design, membrane solutions can analyze and optimize the microstructure of filter membranes and also optimize the design of filter cartridges, selecting the most suitable design solutions for customer needs. In production, we can handle both the preparation of filter membranes and the assembly of filter cartridges. Achieving complete independent research and development and production of filter cartridges ensures the quality and delivery times of slurry filtration filters.

View more products for MLCC Slurry Filtration: