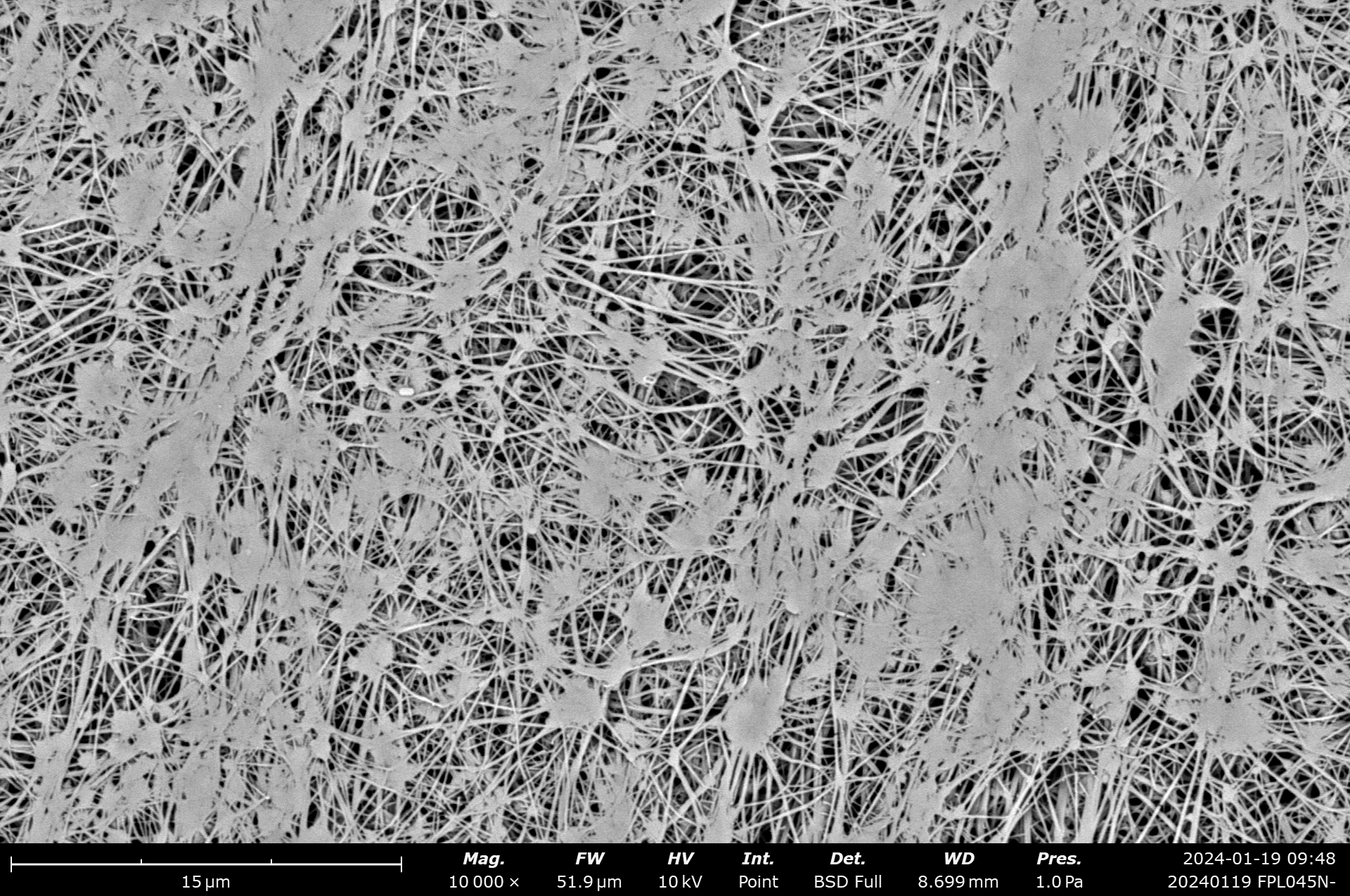

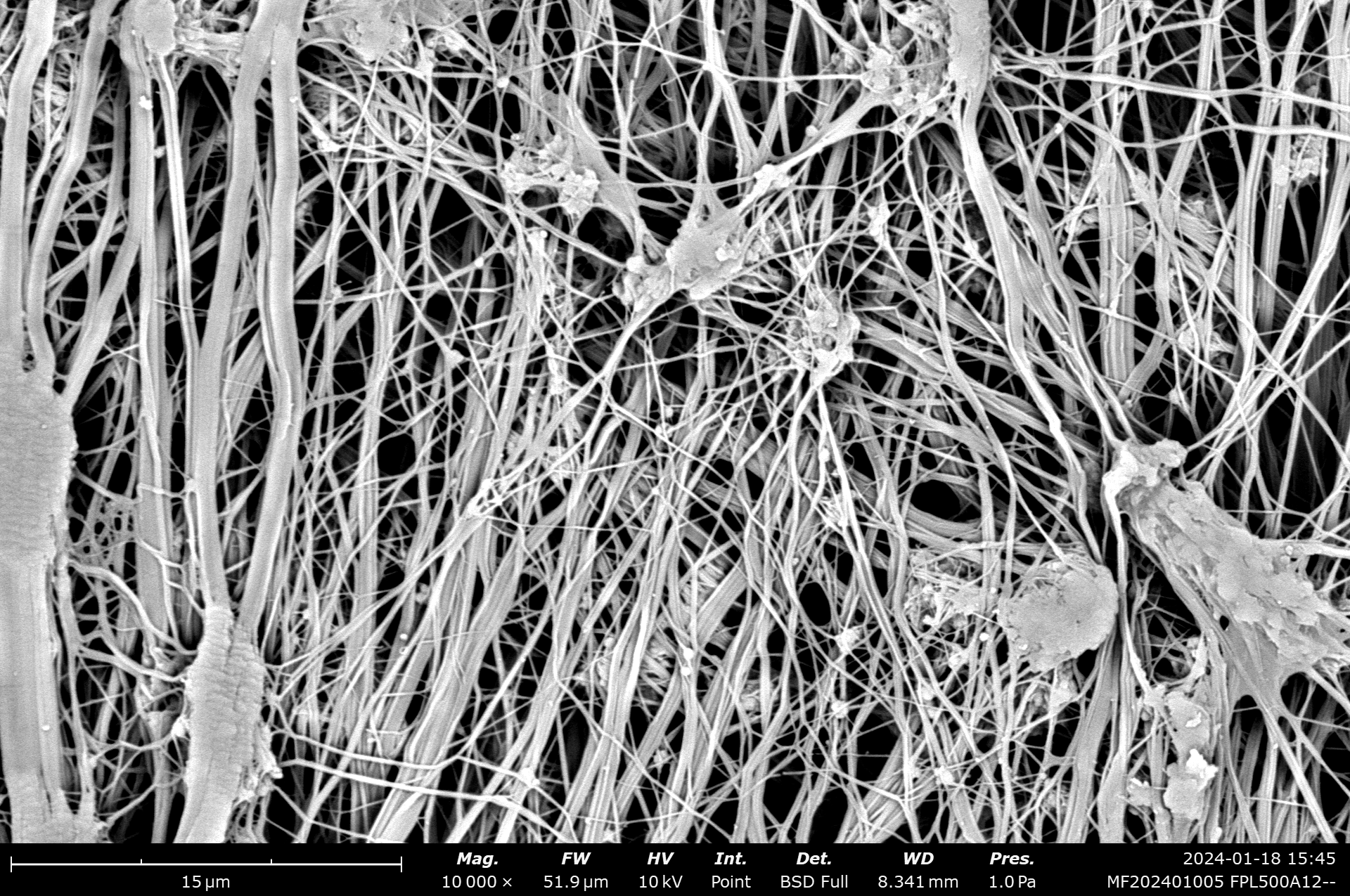

The ePTFE membrane of Membrane Solutions is prepared by mechanically stretching and sintering PTFE particles. Depending on the application requirements, the stretched ePTFE membrane can be thermally compounded with different materials to enhance its mechanical strength. Different modification systems can also be used to functionalize the PTFE membrane. PTFE membranes include ePTFE filtration membranes and ePTFE breathable membranes. Among them, ePTFE filtration membranes include hydrophobic PTFE stretch membranes (supported by different materials) for organic liquid filtration and hydrophilic PTFE membranes (such as MBR membranes) for aqueous filtration; ePTFE breathable membranes include hydrophobic breathable membranes (supported by different materials) and oleophobic breathable membranes (supported by different materials) used for conventional gas equilibrium. According to different usage scenarios and requirements, different choices can be made.

The ePTFE membrane of Membrane Solutions is prepared by mechanically stretching and sintering PTFE particles. Depending on the application requirements, the stretched ePTFE membrane can be thermally compounded with different materials to enhance its mechanical strength. Different modification systems can also be used to functionalize the PTFE membrane. PTFE membranes include ePTFE filtration membranes and ePTFE breathable membranes. Among them, ePTFE filtration membranes include hydrophobic PTFE stretch membranes (supported by different materials) for organic liquid filtration and hydrophilic PTFE membranes (such as MBR membranes) for aqueous filtration; ePTFE breathable membranes include hydrophobic breathable membranes (supported by different materials) and oleophobic breathable membranes (supported by different materials) used for conventional gas equilibrium. According to different usage scenarios and requirements, different choices can be made.

The hydrophilic PTFE filter membrane of Membrane Solutions is prepared by special hydrophilic modification of PTFE base membrane. The special hydrophilic modification process of MS makes it have good hydrophilicity in various chemical environments, long service life, and excellent hydrophilicity. The hydrophilic PTFE membrane with different modified formulas and pore sizes is widely used in various biological sterilization filtration, microelectronic oxidant environmental filtration, and sewage filtration scenarios.

The PTFE hydrophobic filtration membrane of MS is prepared by mechanically stretching and sintering PTFE particles. According to application requirements, the stretched ePTFE membrane can be thermally compounded with different materials to enhance its mechanical strength. It is a key material for solvent and oil filtration applications in the chemical, pharmaceutical, food, and automotive industries.

The PTFE hydrophobic membrane for venting of Membrane Solutions is prepared by mechanically stretching and sintering PTFE particles. According to application requirements, the stretched ePTFE membrane can be thermally compounded with different materials to enhance its mechanical strength. It is widely used in the chemical, pharmaceutical, food, and automotive industries as a key material for breathable packaging, pressure balancing accessories, heat dissipation films, and other applications.

The PTFE oil repellent and breathable membrane of Membrane Solutions adopts PTFE base film surface modification under a special oil repellent modification system to achieve oil repellent function. It is widely used in the chemical, pharmaceutical, food, and automotive industries as a key material for breathable packaging, pressure balancing accessories, heat dissipation films, and other oil use environments.

Releted Document

Product Category

MS Hydrophobic PTFE Membrane

MS Hydrophilic PTFE Membrane

MS Oleophobic PTFE Membrane for Venting

PTFE Hydrophobic Membrane for Venting