MS?Internal/submerged MBR (iMBR)

Request a Quote

The filtration element is installed in either the main bioreactor vessel or in a separate tank. The membranes can be flat sheet or hollow or combination of both, and can incorporate an online backwash system which reduces membrane surface fouling by pumping membrane permeate back through the membrane.

In systems where the membranes are in a separate tank to the bioreactor individual trains of membranes can be isolated to undertake cleaning regimes incorporating membrane soaks. Additional aeration is also required to provide air scour to reduce fouling. Where the membranes are installed in the main reactor, membrane modules are removed from the vessel and transferred to an offline cleaning tank.

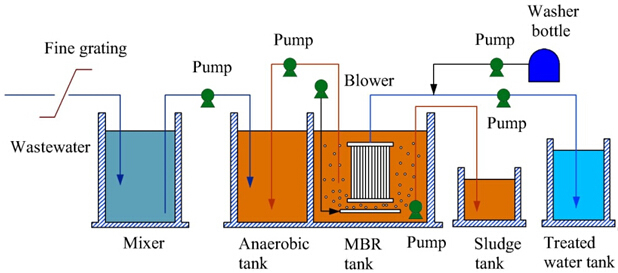

Flow diagram of the MBR

MBR components

| Pretreatment system | Fine grating, Mixer |

|---|---|

| Anaerobic system | Anaerobic tank, Pump |

| Membrane unit system | MBR tank, Membrane module , Membrane frames, Blower |

| Sludge system | Sludge tank, Pump |

| A/O system | A/O tank, Blower |

| Cleaning system | Chemicals, Cleaning pump, Washer bottle |

| Control systems | PLC, Control cabinet |

| Producing water system | Producing water pump, Treated water tank |

More Cartridge Filter Main Page

Membrane bioreactors

External MBR

Ultrafiltration Membrane

PES Ultrafiltration Membrane

PVDF Ultrafiltration Membrane

PTFE Cartridge Filters

PP Cartridge Filters

PVDF Cartridge Filters

MCE Cartridge Filter

Wound Cartridge Filters

Melt Blown Cartridge Filters

Standard Filter Cartridge