What is lenticular filters?

2025-04-15

MS

32

A lenticular filter is a type of filter cartridge that utilizes a wide surface area and the use of depth filtration to maximize retention of solid contaminants.

The main characteristic that makes lenticular filters unique is their accordion-like structure, which is designed to maximize surface area.

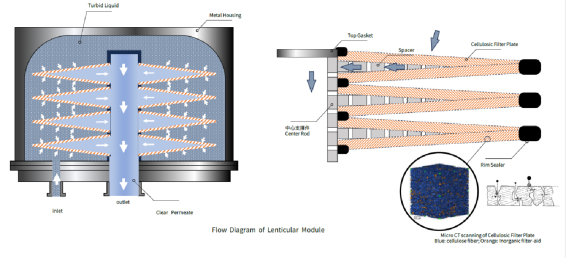

Lenticular filters are made of a series of stacked discs or "cells" attached to a central core.

Each cell is comprised of a rigid polypropylene center support screen sandwiched between two round discs of depth media which are then secured together on the outer edge via a thermally bonded polypropylene band. The completed cell is then thermally bonded to the center core to prevent product bypass. The channel-like structure of the cell interior is designed to direct the flow of liquid toward the central core.

How dose a lenticular filter work:

First, the unfiltered liquid is pushed into the filter housing through the housing's inlet pipe. This is achieved by applying positive pressure to the feeding vessel using either a pump or compressed air. As the liquid flows into the housing, it surrounds the filter and envelops each cell. The pressure forces the liquid into the filter media of the cells.

First, the unfiltered liquid is pushed into the filter housing through the housing's inlet pipe. This is achieved by applying positive pressure to the feeding vessel using either a pump or compressed air. As the liquid flows into the housing, it surrounds the filter and envelops each cell. The pressure forces the liquid into the filter media of the cells.

As the fluid moves through the depth media, it follows what is known as a "tortuous path", meaning it takes a non-linear route. The numerous twists and turns the fluid must take depletes the energy of the particles in the fluid, causing them to become "trapped" within the media.

Unlike standard membrane filters where contaminants are trapped on the surface alone, depth media captures contaminants throughout the entire volume of the media.

Finally, the filtered fluid reaches the center of the cell, where it is channeled into the filter core and down through the outlet pipe of the filter housing.

What are the Benefits of lenticular filter compared with traditional plate and frame filter press ?

There are several advantages of lenticular filter that make it a desirable alternative to plate and frame filters press.

Easy Filter Changeout & Maintenance

Compared with frame filter press, which need to replace filter plates one by one, lenticular filters have a modular design that allows them to be replaced easily and quickly. This results in less downtime spent changing out filters.

Space-saving

The lenticular filter is designed to be placed vertically, and filtration capacity can be increased by adding cartridges to the existing housing, accommodating up to 4 cartridges and mounting vertically or horizontally as required, which have smillar footprint than frame filter press.

Low Startup Costs

The cost of frame filter press,which need the procurement of ancillary machinery and equipment plus corresponding filter plates can easily reach the $100,000 range. Those for $1,000 - $3,000 cost of lenticular housing and filters is more economical.

Fully Closed Loop – No Leaks and more hygienic

Lenticular filter housings are completely closed loop. The product can be handled from start to finish without coming into contact with the atmosphere. This is especially useful for applications handling hazardous or volatile liquids.Also the closed environment avoids direct contact with the air and makes the filtration operation more hygienic.

Applications for Lenticular Filtration

Lenticular filtration is most beneficial for applications where the fluid being processed is heavily saturated with solids.

The applications best suited for lenticular filtration include:

Food and Beverage(wine, beer, syrup,juice)

Pharmaceutical(cell fluid clarification and collection, Microbial fermentation, vaccine production)

Power plant(Condensate Filtration)

Fine chemicals(APIs, heavy industry lubricants)

MS Depth Filter Cartridges is with core filter media of cartridges composed of cellulosic filter paper plate, in which inorganic filter aid like Diatomite Earth and activated carbon, and wet-strength bind resins, to guarantee high filtration efficiency. cartridges pore size rating range covers from 0.04 μ m to 40 μm, specific filtration solutions can be provided according to various customers’ needs.