Membrane Solutions' PFAS-free PES Membrane: Addressing the EU PVDF Ban with a Ready Alternative

2025-10-11

MS

90

Polyvinylidene fluoride (PVDF) membranes face a potential full ban in Europe, following an update to the European Chemicals Agency's (ECHA) dossier that seeks to prohibit the manufacture of all per- and polyfluoroalkyl substances (PFAS).Amid this industry-defining shift, Membrane Solutions leverages its innovative PFAS-free PES membrane technology to deliver mature, reliable sustainable solutions for the food & beverage, water treatment, and other related industries.

I. Forward-Looking Layout: Building a Comprehensive PFAS-free Membrane Technology Matrix

Membrane Solutions demonstrated foresight in the membrane separation industry by anticipating the sustainability challenges of PFAS-containing materials well before the EU's proposed ban. Pioneering PFAS-free PES membrane technology, the company has established a comprehensive product portfolio through sustained R&D, which includes:

- PES Flat-Sheet Membranes: This diverse product line supports applications ranging from precision separation to high-efficiency sterilization, and can be customized to meet specific operational requirements.

- PES Hollow Fiber Membranes: Building on the successful development of modified PES hollow fiber microfiltration membranes in 2019, the company achieved large-scale mass production in 2023—a milestone that demonstrates its strong technological foundation and manufacturing expertise.

II. PES Flat-Sheet Membranes: Precise Grading for All-Round Application

Membrane Solutions’ PES flat-sheet membranes, defined by high performance, a full product lineup, and deep customizability, provide customers with precise filtration solutions:

1. Precisely Graded Product Series

Based on pore size range and separation accuracy, the products are mainly categorized into three series:

- "Precision" Series (Conventional Microfiltration): Covers a pore size range of 0.1μm ~ 5.0μm, focusing on efficient particle retention, solution clarification, sterilization filtration, and pre-filtration.

- "Guardian" Series (Fine Sterilization): Features two precise pore sizes—0.22μm and 0.45μm—to ensure absolute retention of bacteria and microorganisms.

- "Pioneer" Series (High Filtration Capacity): Adopts a highly asymmetric structure, specifically designed for processing large-volume and high-viscosity feed liquids.

2. In-Depth Customization Capabilities

Customization is the core of Membrane Solutions’ PES microfiltration flat-sheet membrane services. Beyond standard products, the company acts as a technical partner to develop tailor-made filtration solutions for customers:

Ø Size & Shape Customization: Membrane sheets of any diameter or square size can be customized to perfectly match customers’ flat-sheet membrane filters, filter cartridges, lenticular filters, or self-made filters.

- Pore Size & Structure Customization: For customers with specific separation targets, Membrane Solutions can adjust the pore size and distribution of flat-sheet membranes within a specific range, and offer options of symmetric or asymmetric membrane structures.

- Surface Modification Customization: Special treatment processes enable membrane surface functionalization (e.g., permanent hydrophilization or hydrophobic/oleophobic modification), endowing PES flat-sheet membranes with specific functions for targeted applications.

3. Key Product Features

- High removal rating, with pore sizes showing an almost normal distribution.

- Gradient distribution of pore sizes (from large to small), enabling multi-level interception of contaminants.

- High flux, high mechanical strength, and high flow rate.

- Low extractables and low protein adsorption.

- Excellent resistance to high temperatures, acids, and alkalis.

4.Basic Operating Characteristics

|

Pore Size Range (μm) |

0.02/0.03/0.05/0.1/0.22/0.45/0.65/0.8/1.0/1.2/3.0/5.0 |

|

Width (mm) |

254-520 |

|

Thickness (μm) |

100-140 |

|

Symmetry |

Asymmetric |

|

pH |

2~12 |

|

Sterilization Methods |

High-temperature steam sterilization, ethylene oxide sterilization, gamma sterilization |

5.Typical Application Specifications

|

Application |

Performance Indicator |

Optional Removal Rating |

|

Clarification & visible particle removal |

Visual transparency |

3-5 μm |

|

Macromolecular organic matter/particle removal |

e.g., yeast and mold removal |

0.6 μm |

|

Bacteria reduction |

Pyrogen control |

0.45 μm |

|

Bacteria retention |

Bacteria removal |

0.22 μm |

|

Small-molecular organic matter removal |

Mycelium removal |

0.1 μm |

Membrane Solutions’ PES flat-sheet membranes are manufactured using a unique formula system and synergistic multi-process preparation. Through special structural design, they not only achieve high-precision filtration capabilities but also adapt to a variety of complex environments and application scenarios. As a driver in the membrane technology field, Membrane Solutions continues to innovate and make breakthroughs, providing more effective membrane products for social development.

III. From Precision Separation to High-Efficiency Filtration: Professional Breakthroughs in PES Hollow Fiber Filters

Complementing its comprehensive flat-sheet membrane portfolio, Membrane Solutions has introduced high-performance PES hollow fiber filters for specialized fluid processing applications. The CleaSep series features a unique open-flow channel design that eliminates dead zones and minimizes shear stress, making it ideal for the beverage industry's stringent requirements to preserve product flavor. This series is available in three precise pore-size ratings: 0.22μm, 0.45μm, and 0.65μm. These options directly address different processing needs:

- 0.22μm hydrophilic hollow fiber microfiltration membranes are designed for wine clarification.

- 0.45μm and 0.65μm membranes are primarily used for beer cross-flow filtration.

Furthermore, all CleaSep modules are certified to US FDA 21 CFR 175-177 for food contact, guaranteeing compliance and safety for the final product.

1.Product Highlights

- Safe and reliable raw material selection, with US FDA 21 CFR 175-177 food-grade certification.

- Multiple options for removal rating and filtration area.

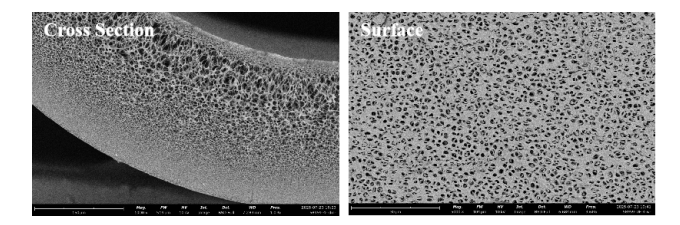

- Excellent chemical resistance (suitable for chemical cleaning).

- Highly asymmetric cross-sectional structure and high porosity surface structure, endowing the hollow fiber membranes with higher filtration capacity and flux.

2.Filtration Performance

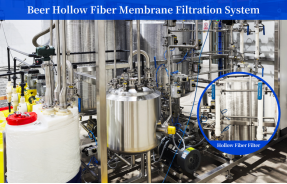

Beer Hollow Fiber Filter Filtration System

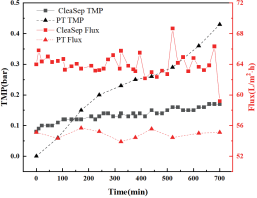

Taking beer cross-flow filtration as an example, the highly asymmetric structure of CleaSep series hollow fiber membranes demonstrates excellent operating flux and filtration capabilities:

A test was conducted using industrial beer of the same variety produced by the WZ factory of a Swedish Brand B. Under the same conditions (including pretreatment, filtration temperature, and feed liquid turbidity), cross-flow clarification filtration was performed. The results showed that compared with the competitor’s PT membrane, the CleaSep series hollow fiber filters achieved higher operating flux (CleaSep: 64 L/m²·h vs. Competitor PT: 55 L/m²·h), while the increase in transmembrane pressure (TMP) was much gentler (CleaSep: 0.77kPa/h vs. Competitor PT: 3.68kPa/h). Additionally, the turbidity of the permeate at both 90° and 25° met the customer’s requirements.

Note: Higher flux indicates better filtration efficiency; a smaller increase in TMP reduces the frequency of backwashing and chemical cleaning, thereby lowering chemical reagent consumption and energy consumption.

Why Choose Membrane Solutions?

- Forward-Looking Technology Layout: PES membranes eliminate PFAS from the design source, aligning with the latest EU regulatory trends.

- Full-Scenario Coverage: From flat-sheet membrane precision separation to hollow fiber cross-flow filtration, meeting the needs of water treatment, food & beverage, pharmaceutical, and other fields with PFAS-free solutions.

- In-Depth Customization: From pore size adjustment to surface functionalization, providing targeted filtration solutions for customers.

- Proven Application Validation: The products have served numerous projects worldwide, with their performance and reliability verified through long-term practice.

Ready for a PFAS-Free Future

Membrane Solutions does not merely provide PFAS-free alternative solutions—it redefines filtration efficiency and sustainability through technological innovation. As the implementation of the EU PFAS ban enters the countdown phase, we look forward to collaborating with partners across various industries to jointly move toward a new era of green, PFAS-free filtration.

Welcome to contact our technical team to obtain customized PFAS-free membrane solutions.