Membrane Solution All PTFE Chemical Filter: (Pre Wet) Technology Makes Filtration More Efficient

2025-04-07

MS

67

Why Should Filter Cartridges Be Pre-Wetted?

The essence of pre-wetting filter cartridges is to optimize material functionality, control contamination, and enhance operational convenience through liquid infiltration. The necessity of pre-wetting depends on the characteristics of the filter material (such as hydrophilicity/hydrophobicity and pore structure) and the requirements of the application scenario (such as medical sterility or industrial efficiency).

In general, both hydrophilic and hydrophobic membrane materials should be wetted before use. Hydrophobic membranes have surfaces that repel water or other polar liquids, causing liquid droplets to form spherical beads that roll off the surface. Typically, hydrophobic filters—such as all-Teflon filters or PTFE membrane filters—require pre-wetting with an organic solvent before being used for filtering aqueous solutions.

Advantages of Pre-Wetted Packaging

1. Maintaining Stable Filter Performance

• Prevents material drying and deformation: Some filter materials (such as polymer membranes and fiber membranes) may shrink or undergo pore structure changes when dried, leading to reduced filtration efficiency. Pre-wetted packaging keeps the filter in a moist state, preserving its physical structure and functional integrity.

• Eliminates initial bubble issues: Dry filters may trap air due to insufficient wetting upon first use, affecting filtration system efficiency. Pre-wetting removes air in advance, ensuring a quick and stable system startup.

2. Plug-and-Play,Simplified Operation

• No user pre-treatment required: Users can directly install the pre-wetted filter cartridge without the need for soaking or rinsing, making it especially suitable for applications requiring high operational convenience, such as medical devices (e.g., dialysis machines) and microelectronics production lines.

• Reduces system startup time: Pre-wetted filters provide immediate filtration performance, minimizing system setup time and improving overall productivity.

3. Enhanced Filtration Efficiency and Consistency

• Optimized initial filtration performance: Pre-wetting ensures filter pores are fully open, preventing flow fluctuations during initial use and achieving the designed filtration standard from the start.

• Minimizes particle release risk: Dry-packed filters may release fine particles due to environmental contamination or material friction during wetting. Pre-wetted packaging mitigates this risk by pre-soaking the filter to reduce the potential contamination.

Pre-Wetting and Packaging Process

1. Soaking the Filter Cartridge

Fully immerse the filter cartridge in the pre-wetting liquid (for hydrophobic PTFE, use 95% ethanol, 60%, or 100% isopropanol) to ensure the liquid covers all surfaces.

• Soaking Time:

• Standard filter cartridges (e.g., PTFE membrane/PP membrane): 10–30 minutes

• Polymeric membrane cartridges (e.g., RO membrane, UF membrane): 1–2 hours (to ensure full pore infiltration)

• Key Point: Lightly tap the filter housing or gently shake the container to expel internal air bubbles.

2. Rinsing the Filter Cartridge

Remove the filter cartridge from the pre-wetting liquid and rinse it vertically with ultrapure water/purified water or install it in a flushing system for inline rinsing.

• Flushing Directions:

• Forward flushing: The liquid flows in the same direction as normal filtration (applicable to most filter cartridges).

• Reverse flushing: Some filters require reverse flushing to remove residual impurities (e.g., hollow fiber membranes).

• Flow Rate Control: Rinse slowly to prevent pressure shock that could damage the filter material structure.

Pre-Wetting and Packaging Process

1. Soaking the Filter Cartridge

Fully immerse the filter cartridge in the pre-wetting liquid (for hydrophobic PTFE, use 95% ethanol, 60%, or 100% isopropanol) to ensure the liquid covers all surfaces.

• Soaking Time:

• Standard filter cartridges (e.g., PTFE membrane/PP membrane): 10–30 minutes

• Polymeric membrane cartridges (e.g., RO membrane, ultrafiltration membrane): 1–2 hours (to ensure full pore infiltration)

• Key Point: Lightly tap the filter housing or gently shake the container to expel internal air bubbles.

2. Rinsing the Filter Cartridge

Remove the filter cartridge from the pre-wetting liquid and rinse it vertically with ultrapure water/purified water or install it in a flushing system for inline rinsing.

• Flushing Directions:

• Forward flushing: The liquid flows in the same direction as normal filtration (applicable to most filter cartridges).

• Reverse flushing: Some filters require reverse flushing to remove residual impurities (e.g., hollow fiber membranes).

• Flow Rate Control: Rinse slowly to prevent pressure shock that could damage the filter material structure.

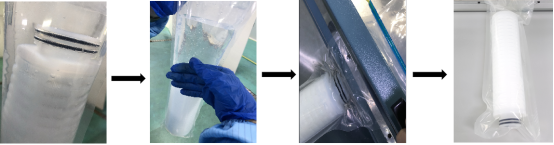

3. Pre-Wetted Packaging

Rinse the pre-wetted packaging bag multiple times with ultrapure water. Place the rinsed filter cartridge into the packaging bag with the outlet facing upward. Seal the bag at a position 10–20 cm above the filter cartridge outlet.

• Packaging Steps:

• Lightly tap the bag to expel air and excess liquid.

• Use a sealing machine to heat-seal the bag.

• Enclose the heat-sealed product in a second layer of packaging and apply vacuum processing.

This completes the pre-wetted packaging operation for the filter cartridge.

Filter cartridge pre-wet packaging operation

Superior All PTFE Chemical Filter

Membrane Solutions’ All PTFE chemical filter utilizes advanced polytetrafluoroethylene (PTFE) material, renowned for its exceptional chemical stability, high-temperature resistance, and low adsorption properties. This filter can withstand almost all chemical solvents, effortlessly handling strong acids, strong bases, and organic solvents, ensuring stability and safety throughout the filtration process.

In terms of filtration performance, Membrane Solutions’ Wet-Fluoride series features an all-Teflon structure, offering high flow rates and low resistance. Its unique pleated design significantly expands the filtration area, enhancing efficiency. Additionally, the filter’s uniform and stable pore structure effectively captures fine particles, ensuring the filtered liquid achieves ultra-high purity.

The Membrane Solutions’ AfsPure All Fluorine Series filter cartridge is composed of high-porosity PTFE membranes and high-purity PFA components, offering excellent resistance and stability in highly corrosive acid, alkali, and organic solvent environments.

The Membrane Solutions’ AfsPure All Fluorine Series filter cartridge is composed of high-porosity PTFE membranes and high-purity PFA components, offering excellent resistance and stability in highly corrosive acid, alkali, and organic solvent environments.

With advanced post-processing and 18.2 MΩ·cm ultrapure water cleaning, it achieves a consistently high level of cleanliness, ensuring filtration stability. This makes it the most cost-effective solution for high-purity electronic chemical filtration in the semiconductor industry.

The Membrane solutions’ Wet-Mega Series filter cartridge features PTFE membrane as the filtration layer, combined with a high-purity PP support layer and plastic components. It offers extremely low extractables and minimal particle shedding, excellent chemical resistance, high flow rates, and an extended service life.

The Membrane solutions’ Wet-Mega Series filter cartridge features PTFE membrane as the filtration layer, combined with a high-purity PP support layer and plastic components. It offers extremely low extractables and minimal particle shedding, excellent chemical resistance, high flow rates, and an extended service life.

This series is available in ultrapure water pre-wetted packaging, making it ideal for filtering electronic chemical reagents compatible with PP. By reducing replacement frequency, it helps lower operational and maintenance costs.

The Membrane Solutions’ Wet-Vast Series filter cartridge is made with high-purity HDPE components, ensuring extremely low extractables and excellent chemical compatibility.

The Membrane Solutions’ Wet-Vast Series filter cartridge is made with high-purity HDPE components, ensuring extremely low extractables and excellent chemical compatibility.

The PTFE membrane can be configured as either hydrophobic or hydrophilic, depending on the application. Additionally, a pre-wetted packaging option is available, making it suitable for various chemical solutions.

This series effectively removes microparticles from high-purity chemicals used in the semiconductor industry, meeting the requirements of most customers.

As a professional filtration solutions provider,Membrane Solutions(Nantong) Co., Ltd. is committed to delivering high-quality products and services. Membrane solutions’ All PTFE filters, with their outstanding performance, innovative pre-wetting technology, and wide applicability, have earned good reputation in the filtration industry.

No matter which industry you are in, Membrane Solutions can offer you efficient and reliable filtration solutions. Feel free to contact us to learn more about Membrane solutions’ microelectronics filtration products and application cases.

Click here to explore our products

1. Wet-FluorideSeries(http://www.zsxmh.com/wet_fluoride_all_fluorine_filter_cartridge.htm)

2. AfsPure All Fluorine Series

(http://www.zsxmh.com/ptfe_pfa1.htm)

3. Wet-Vast Series

(http://www.zsxmh.com/wet_vast_ptfe_pleated_filter_cartridge.htm)

4. Wet-Mega Series

(http://www.zsxmh.com/wet_mega_ptfe_pleated_filter_cartridge.htm)