Melt Blown Filter: Features, Benefits, and Applications

2025-03-25

MS

15

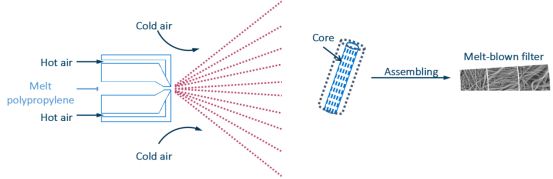

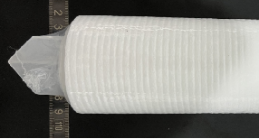

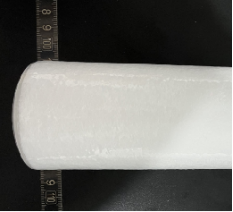

The polypropylene (PP) melt-blown filter element is a tubular filtration device manufactured through a sophisticated process that involves heating, melting, extruding, and drawing polypropylene pellets. This intricate manufacturing process allows the material to solidify into its final form, creating a highly efficient and reliable filtration solution. When polypropylene serves as the primary raw material, this type of filter element is referred to as a PP melt-blown filter element.

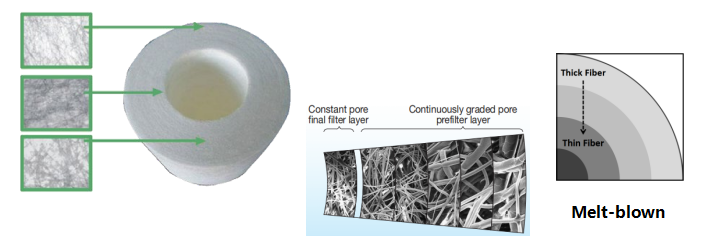

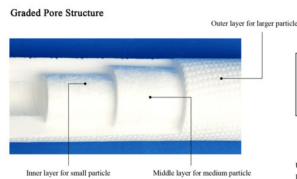

The polymer melt streams extruded from the spinnerets of the die are stretched by a high-speed hot air flow to form ultrafine fibers, which are collected on a dedicated central rod to achieve self-adhesion between the fibers. The raw material fibers are randomly arranged in space to form a three-dimensional microporous structure, and the micropore diameters are gradient-distributed along the liquid flow direction.

Advantages

- Excellent chemical compatibility

Polypropylene is widely recognized for its excellent chemical compatibility, making it suitable for use in a variety of industries, including pharmaceuticals, food and beverage processing, and water treatment. The material's resistance to a broad range of chemicals ensures that it can effectively filter out contaminants without degrading or reacting with the substances passing through it.

- Long service life

In addition to its chemical compatibility, the PP melt-blown filter element boasts a long service life. This longevity is attributed to the robust nature of polypropylene, which maintains its structural integrity even under challenging operating conditions. The filter element can withstand high temperatures, varying pressures, and prolonged exposure to different types of fluids, ensuring consistent performance over an extended period.

- Cost-effectiveness

Furthermore, the cost-effectiveness of PP melt-blown filter elements makes them an attractive option for businesses looking to optimize their filtration processes without compromising on quality. The relatively low production costs associated with polypropylene, combined with the durability and efficiency of the filter elements, provide a compelling value proposition for users across various industries.

Overall, the combination of excellent chemical compatibility, long service life, and cost-effectiveness positions the polypropylene (PP) melt-blown filter element as a preferred choice for many filtration applications.

Key Applications

- Seawater desalination: RO reverse osmosis pre-filtration

- Electronics industry: pre-filtration of pure water and ultra-pure water

- Power plant water treatment: cooling water filtration, boiler brine removal

- Biopharmaceutical, water for injection and other pure water pretreatment

- Drinking water filtration: food, beverage and bottled water filtration

- Electroplating solution filtration

- Oil/gas industry pretreatment, oil field reinjection water filtration

Melt Blown Filter Features

- Gradient pore size structure, high dirt holding capacity

- High-purity PP material, extensive chemical resistance

- Uniform void distribution, high filtering effect, large area

- Double the service life and low replacement costs

- Inner ironing treatment and PP core structure to avoid fiber precipitation

MS Melt Blow Filter Series

- Flat

- Orange

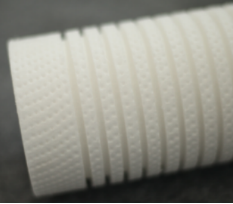

- Embossing

- Grooved

- High Dirt Holding

Conclusion

For more detailed insights and inquiries about Melt Blown Filter, please visit the Membrane Solutions website at www.zsxmh.com. You can leave a message or follow us for updates on our latest products and innovations. We’re here to assist you with your filtration needs and provide tailored solutions that meet your specific requirements. Don’t hesitate to reach out!