Introduction to Positively Charged Nylon Membrane of Membrane Solutions

2025-05-16

MS

1

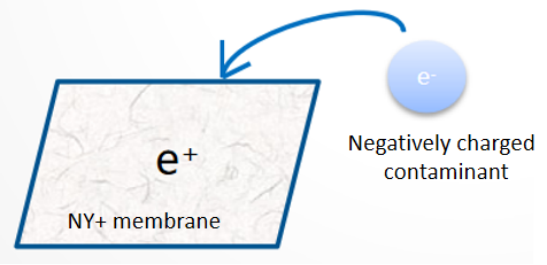

In the liquid filtration industry, nylon membrane is one of the most widely used microporous membranes due to its excellent chemical compatibility and mechanical properties, especially in laboratory filtration, chemical industry, and food and beverage industry. The filtration principle of nylon membrane is the same as that of most microfiltration membranes. It mainly retains substances larger than the pore size of the membrane through screening principle. For substances smaller than this pore size, the retention effect cannot be guaranteed. In response to this situation, Membrane Solutions has specially developed a positively charged nylon microporous membrane, which modifies the conventional nylon membrane with positive charge to fill the membrane surface with positive charge groups, and then adsorbs and retains negatively charged substances smaller than the pore size of the membrane in the liquid.

The common positive charge modification methods are mainly divided into two categories:

Chemical modification method, which involves grafting or adsorbing positively charged groups such as quaternary ammonium salts and polyelectrolytes onto the surface of nylon membrane through chemical reactions. These functional groups can form stable chemical bonds with nylon membranes, giving the membrane surface a persistent positive charge.

Physical adsorption method is the use of physical adsorption to adsorb positively charged molecules or polymers onto the surface of nylon membrane. Although the charge adsorption formed by this method may not be as stable as chemical modification methods, it still has significant advantages in certain specific application scenarios. The positively charged modified nylon membrane not only retains the excellent properties of the original membrane material, but also endows the membrane material with new functional characteristics. The high charge density on the membrane surface can efficiently capture negatively charged biomolecules such as nucleic acids and endotoxins, making it more widely applicable in the field of biopharmaceuticals.

The modification technology used in Membrane Solutions' positively charged nylon membrane is chemical modification, which involves grafting quaternary ammonium ions onto the surface of the nylon membrane to form a stable chemical bond with the membrane. This ensures that the positive groups have a long-lasting effect on the membrane, enhancing its durability and aging resistance. The surface charge is indirectly characterized by testing the adsorption capacity of negatively charged metanil yellow by the positively charged membrane. The modified base membrane is a nylon microporous membrane independently developed and produced by Membrane Solutions, so the pore size can be precisely controlled and customized according to customer needs from 0.05um to 3.0um. The entire production modification process of the product strictly controls the cleanliness to ensure the dissolution data of the finished membrane and avoid downstream influences. At present, this product is mainly used for sterilization applications in food and beverages, as well as for the removal of endotoxins in biomedicine.

It is well known that the isoelectric points (pI) of most bacteria are within the pH range of 2 to 5; therefore, in neutral or alkaline solutions, bacteria typically carry a negative charge. This negative charge enables them to be adsorbed and retained by the positively charged surface of modified nylon membranes. Meanwhile, endotoxins - primarily composed of lipopolysaccharides (LPS) carrying negative charges - are also readily adsorbed by positive charges. Test results demonstrate that Membrane Solutions' 0.22μm positively charged nylon membrane achieves a Log Reduction Value (LRV) of 7 for Brevundimonas diminuta bacterial retention, while its endotoxin adsorption capacity reaches 1.11×10? EU/cm². In terms of biosafety, Membrane Solutions' positively charged nylon membranes are certified by the FDA (FDA 21 CFR 177.1500), accompanied by SGS RoHS compliance test reports, and have passed USP Class VI in vitro cytotoxicity testing. The membranes exhibit superior retention performance for both bacteria and endotoxins through electrostatic adsorption mechanisms, with comprehensive certifications ensuring their safety and efficacy for biomedical applications.

In addition to positively charged nylon membranes, Membrane Solutions also provides MinyPure-NZ Series positively charged modified Nylon 6.6 pleated filter cartridges and positively charged capsule filters, which have excellent retention effects on Brevundimonas diminuta and endotoxins, and can be specially designed according to the retention effect.

In addition, positively charged nylon membranes and filters have a wide range of applications in biopharmaceuticals and food and beverage industries, as well as key applications in chemical reagents and purified water fields. This is because there are some small negatively charged bacteria or colloids in the terminal processing of these industries, which are difficult to remove through conventional mechanical retention. Therefore, positively charged nylon membranes are a very good choice.