High-Flow cartridge filter : a solution to improve drinking water quality

2025-04-08

MS

1

In modern society, the safety and purity of drinking water are increasingly valued. As a key component in drinking water treatment systems, high-flow filters play a vital role. This article will discuss in detail the application of high-flow filters in drinking water treatment and their operating mechanism to help readers fully understand their importance and practical operation.

MS high-flow filter element is a filter device for treating high-flow water bodies and is widely used in drinking water treatment systems. The pore size of MS high-flow is between 0.1 micron and 100 microns, which can effectively remove suspended particles, bacteria, algae and other large particles of impurities in the water. High-flow filter elements can treat large amounts of water in a short period of time and are suitable for municipal water supply, industrial water and large community needs. Through regular maintenance and replacement, high-flow filter elements can ensure the safety and purity of water quality and extend the service life of subsequent treatment equipment.

High flow filter element VS wire wound filter element and melt blown filter element

The large-flow pleated filter element has excellent performance in filtration efficiency, dirt holding capacity, pressure drop and service life, and is suitable for a variety of high-flow and high-precision filtration needs.

Filtration efficiency

The high-flow pleated filter can provide higher filtration efficiency due to its multi-layer pleated structure. Under the same filtration accuracy, the filtration efficiency of the high-flow pleated filter is more than 20% higher than that of the wire wound filter and the melt blown filter .

Pollution holding capacity

Meltblown filter are suitable for highly polluted environments due to their high dirt holding capacity. However, high-flow pleated filter elements have a high dirt holding capacity while maintaining high filtration efficiency by optimizing filter materials and structural design. The dirt holding capacity of high-flow pleated filter elements is more than 30% higher than that of wire wound filter .

Service life

The service life of large flow pleated filter is significantly longer than other types of filter due to its high efficiency filtration and long life design. The service life of large flow pleated filter element is 2-3 times longer than that of wire wound filter and melt blown filter

|

|

Large flow pleated filter element |

Wirewound filter element |

Meltblown filter element |

|

Filtration accuracy |

0.1–100 |

1-100 |

1-100 |

|

Filter area |

0.5 – 10 |

0.1-1 |

0.1-1 |

|

Pressure Drop |

10-50 |

20-100 |

30-150 |

|

Service life |

1000-5000 |

500-2000 |

300-1000 |

Why choose MS high-flow filter element

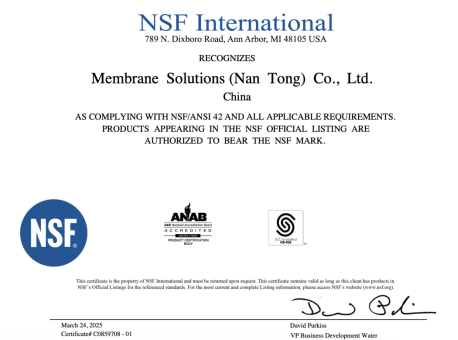

NSF 42 certification: MS high-flow filter element has obtained NSF 42 certification, which is a standard established by the National Sanitation Foundation (NSF International). This means that MS high-flow filter element can not only ensure the basic performance of drinking water treatment equipment, but also play a good role in improving the taste, odor and appearance of drinking water.

Various models for your choice: MS can provide various models of high-flow pleated filter cartridges, including various foreign alternative products, including: Pall high-flow pleated filter cartridges, 3M high-flow pleated filter cartridges, Parker high-flow pleated filter cartridges, etc.

Good design save your cost: MS High Flow Filter Cartridge is made of deep polypropylene or resin synthetic glass fiber membrane, with a large diameter of 152mm/165mm and a single opening design. The large diameter ensures a large filtration area and increases the filtration flux, thereby reducing the number of filter cartridges and filters. Long service life and high flow rate greatly save equipment investment input cost and labor cost.

For more detailed insights and inquiries about High Flow Filter Cartridge, please visit the Membrane Solutions website at www.zsxmh.com. You can leave a message or follow us for updates on our latest products and innovations. We’re here to assist you with your filtration needs and provide tailored solutions that meet your specific requirements. Don’t hesitate to reach out!

For more detailed insights and inquiries about High Flow Filter Cartridge, please visit the Membrane Solutions website at www.zsxmh.com. You can leave a message or follow us for updates on our latest products and innovations. We’re here to assist you with your filtration needs and provide tailored solutions that meet your specific requirements. Don’t hesitate to reach out!