Granular Activated Carbon Filter(GAC Filter)

2025-04-08

MS

37

At Membrane Solutions, we specialize in advanced filtration technologies designed to enhance water quality and optimize industrial and commercial water treatment processes. Our Granular Activated Carbon (GAC) Filters provide an essential pre-treatment solution for Reverse Osmosis (RO) systems, effectively removing chlorine, chloramines, organic contaminants, and various chemical pollutants that can compromise membrane performance and longevity.

What is granular activated carbon used for?

Granular activated carbon (GAC) generally is an organic carbon filtration media — wood, coconut shells, coal or peat — used for water purification, typically applied in a fixed bed application.

A filter with GAC can remove certain chemicals, particularly organic contaminants, from water, as well as chemicals that produce odors or tastes to water such as hydrogen sulfide or chlorine. Granular activated carbon notably assists with the removal of per- and polyfluoroalkyl substances (PFAS), which have become an increasing contaminant of concern for regulators.

Other chemicals, specifically iron and nitrate, can not be removed with GAC. GAC should be changed based on contaminant levels and water use, as higher levels or use may require more frequent change-outs.

How Granular Activated Carbon is Created:

Pulverization: The base product, typically coal, is crushed into a fine powder.

Agglomeration: The carbon powder is reagglomerated (ie reformed) into briquettes under several tons of pressure.

Crushing: Briquettes are crushed to achieve the desired particle size.

Baking: Baked at temperatures up to 800 degrees F to remove VOCs.

Activation: Thermally-activated with exposure to temperatures up to 1900 degrees F. Activation is done within a controlled atmosphere using oxygen, stem, acid or salts.

Screened / Sorted: Separated by size, shape and use.

What are the advantages and disadvantages of granular activated carbon?

Granular activated carbon (GAC) is used extensively in Europe and the United States for the removal of micropollutants such as pesticides, industrial chemicals and tastes and odours. It is also becoming more widely used in Australia, particularly for taste and odour removal and insurance against the possibility of a toxic algae bloom in the water source. The particle size is larger than that of PAC, usually between 0.4 and 2.5 mm. Granular activated carbon is generally used as a final polishing step, after conventional treatment and before disinfection. The advantages of GAC are that it provides a constant barrier against unexpected episodes of contamination of water sources, and the large mass of carbon provides a very large surface area. The disadvantage is that it has a limited lifetime, and must be replaced or regenerated when its performance is no longer sufficient to provide high quality drinking water. Replacing the GAC on a regular basis results in high on-going treatment costs. The regeneration process involves heating the carbon to very high temperatures to volatilise the adsorbed compounds. The costs associated with this process are the capital costs of establishing a regeneration facility, or transport to an existing facility, energy costs, and the loss of some of the GAC through attrition.

Filtration through GAC is often used in conjunction with ozone. When used in conjunction with ozone it is sometimes called BAC, or biological activated carbon; however, this is a misnomer as all GAC filters function as biological filters within a few weeks to months of commissioning.

Key Features of Membrane Solutions’GAC Filters

l High Adsorption Capacity – Superior removal of chlorine and organic impurities.

l Optimized for RO Pre-Treatment – Protects RO membranes from chemical degradation.

l Multiple Media Options – Available in coal-based, coconut shell, and wood-based carbon.

l Enhanced Bacteria Resistance – Reduces microbial growth risks with premium-grade carbon.

l Customizable Configurations – Offered in various sizes to meet diverse application needs.

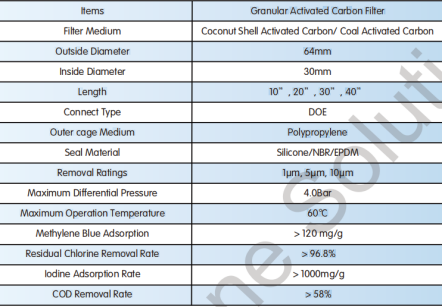

Specification

Conclusion

Membrane Solutions Granular Activated Carbon (GAC) Filters offer high adsorption efficiency, effectively removing chlorine, chloramines, organic compounds, and other contaminants to ensure cleaner, safer water. They help protect Reverse Osmosis (RO) systems from oxidation damage and membrane fouling while providing stable flow rates and extended service life, reducing maintenance and operational costs.

Widely used in RO pre-treatment, drinking water filtration, industrial water treatment, and chemical processing, our GAC filters deliver cost-effective and reliable performance for both residential and commercial applications.

For more information, visit www.zsxmh.com. Our team is ready to assist you in finding the best filtration solution for your needs!