Drinking Water Treatment: Process and Importance for Ensuring Clean Water

2025-04-08

MS

1

Water is the source of life, and approximately 50% to 60% of the human body is water, which is an important substance necessary for maintaining normal physiological functions. According to a survey by the World Health Organization (WHO), 80% of diseases are related to drinking water.Due to natural and human factors, raw water contains various impurities and may be contaminated by various microorganisms such as bacteria and viruses.

Why drinking water becomes so necessary?

The purpose of water treatment in a water plant is to remove suspended substances, colloidal substances, bacteria, and other toxic and harmful substances that can harm human health, so that the purified water (commonly known as tap water) meets the needs of drinking water for daily life. So, the process treatment of drinking water become so important.

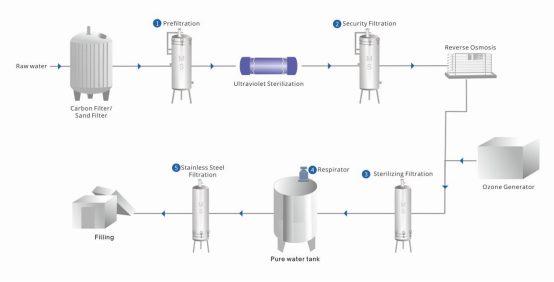

How does drinking water treatment process?

Membrane filtration technology is becoming the technology of choice for safe drinking water. Suspended particles, microorganisms and some soluble salts must be removed as they can contaminate drinking water and have a negative impact on public health. Membrane Solutions provides a variety of filters to meet different requirements of water quality.

Pre-filtration

Pre-filtration removes particles that cause premature scaling in RO system, protecting high-pressure pumps and RO system. A good pre-filtration system can significantly improve influent water quality with low SDI and turbidity values before entering the RO system. MS filter element can help you effectively extend the service life of RO membrane and reduce system costs.

Security Filtration

Security filters use filter cartridges as filtering media. These filters can be made of various materials, such as polypropylene (PP) melt blown filters, wire wound filters, folding filters, etc.Its main function is to remove particulate impurities: Security filters can intercept suspended particles, colloids, and microorganisms with a diameter larger than the filter aperture (usually 5 microns), ensuring the cleanliness of water quality to next step

Final Filtration

Final filtration is used to ensure the final sterile filtration process and to remove particles, bacteria and heat sources.

After understanding the process needs of customers, Membrane Solutions provides customers with stable and reliable products for a long time, and can provide perfect filter cartridge process validation. Its recommendations for the filtration and applications of the main sites in the process of municipal water are as follows:

|

Recommended MS products |

|

|

① Pre treated |

MS_600 FlowPure HF high flow folding filter cartridge |

|

NMO series nylon monofilament filter bag |

|

|

Needle punched felt filter bag (PP/PE/PTFE series) |

|

|

PolyPure Classical series (PPC series) high throughput, high flow rate polypropylene folding filter cartridge |

|

|

② Security filter |

PolyPure Classical series (PPC series) high throughput, high flow rate polypropylene folding filter cartridge |

|

MicroPure Classic series PP melt blown filter cartridge |

|

|

③Terminal sterilization filtration |

SteriPure series (SP series) high flow rate and long service life polyether sulfone membrane folding filter cartridge for terminal sterilization filtration |

|

SteriPure-B series (SPB series) high flow rate, high-efficiency sterilization grade polyether sulfone membrane folding filter cartridge |

|

|

SteriPure-P series (SPP series) long service life, high-efficiency sterilization grade double-layer polyether sulfone membrane folding filter cartridge |

|

|

SteriPure-D series (SPD series) ultra efficient sterilization grade double-layer polyether sulfone membrane folding filter cartridge |

|

|

PolymidPure series (PN series) high-strength, high-temperature resistant nylon 66 film folding filter cartridge |

|

|

④ FSG series |

FluorPure SG series (FSG series) PTFE membrane folding filter cartridge that meets GMP gas sterile filtration requirements |

|

The FluorPure BG series (FBG series) of respirators is a cost-effective PTFE membrane folding filter cartridge that meets GMP requirements for sterile gas filtration |

For detailed technical solutions and product series information, please contact MS sales engineer.